Businesses around the world were jostled into an uncertain pandemic induced catastrophe. Supply chain related issues were usually not a matter of concern for CEOs. However, we saw some supply chain disruption examples in 2020 that have forced us to reconsider the fragility of our supply chains.

Contents

Types of supply chain disruptions

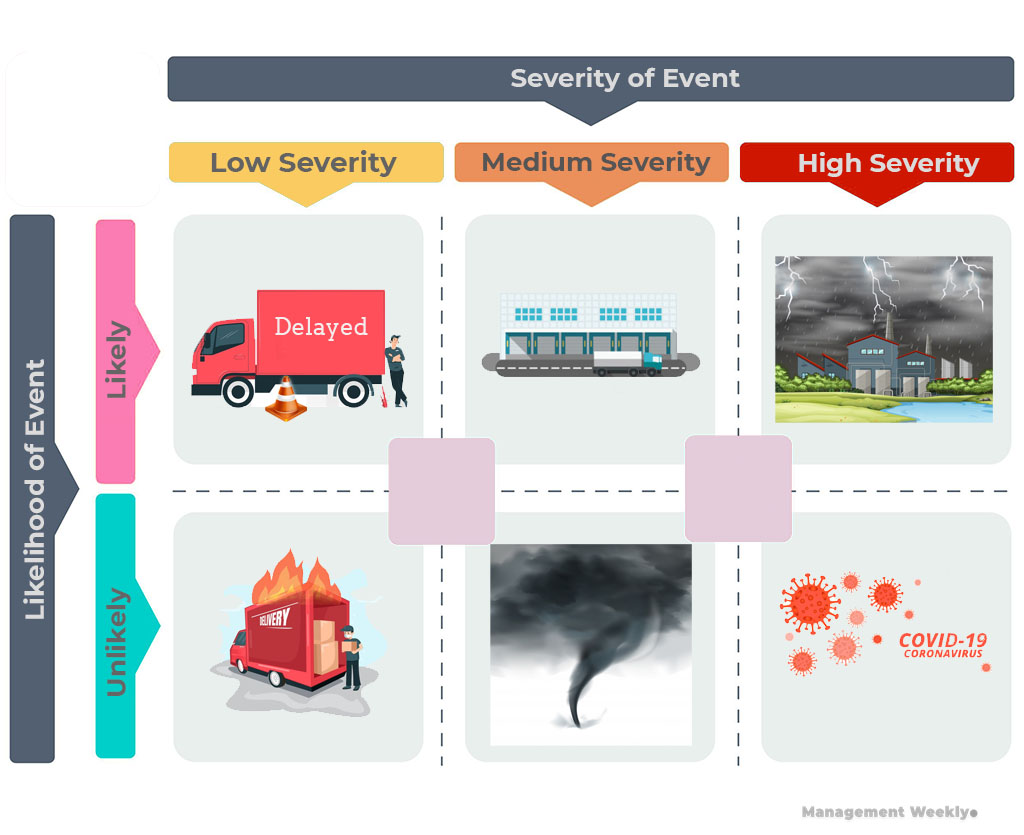

Supply chain disruptions can be in any form. However, it makes our analysis simpler if we typify them based on two factors: their severity and probability of occurrence. Firstly, we can easily bifurcate the disruptions based on their impact on the firm. We can classify events that have three levels of severity: low, medium, and high. Secondly, we can also look at events that have a higher probability of occurrence versus those that are less probable.

Low severity events

A low severity event is one that has few key features: firstly, it should only have a short-term impact. One of the examples of such an event would be a weather-induced delay in transportation. Such events would impact the supply chain only in the short run. In the subsequent cycles, the supply chain works as usual. Secondly, it should have a low monetary impact. An event with a lower monetary impact like theft of a few items from a lot. Thirdly, it should have a lower downstream effect. For example, the impact of pilferage of a batch of goods would not impact the subsequent batches. It is a one-time event with no impact on subsequent cycles.

Medium severity events

The medium severity events are those that have an impact on the medium-term ranging from few weeks to months. If we consider an event such as damage to the warehouse, it is supply chain disruption examples. In such cases, the medium severity events will lead to losses that are reflected in the quarterly financial statements of a company. These events also have some downstream impact. However, their downstream impact would be moderate. For instance, disruption in the warehouse may increase the delivery time for the products. It could also impact other timelines like lead time.

High severity events

A high severity event would be most challenging for any supply chain manager. These types of events can have either long-term impact or higher monetary impact or down-stream impact on the supply chain or a combination of any of these. Firstly, certain disruptions can cause sustained damage for a long duration. These damages are typically reflected in the annual report as well. One of the examples would be covid19 induced impact on the supply chain. One of the long-term solutions to such supply chain disruption examples is through the development of resilience.

Firms relentlessly pursued to rectify the shock on their supply chains for several months. Secondly, we have events that have huge monetary impacts like a pandemic or extreme weather phenomena. A super-cyclone may destroy a factory leading to mega financial losses for a firm. Finally, we can also have high severity events that can throw the entire system into disarray. When the Covid19 struck the world, it not just caused the irregularity in the supply chain. It also led to the delays in delivery of products as well as major setbacks for R&D of new products as well.

Likely events

In a world of constant information, it is obvious that we need to focus our attention on pertinent issues. Supply chain management is no exception. While the managers are barraged with small and big issues, the question is what events typically draw the most attention? These are the high probability events. Organizational learning gives us a certain understanding of the internal and external environment. This helps us understand and predict such supply chain disruptions. The high probable events are therefore those events that are perceived to have a higher chance of occurring in a given time frame.

A simple example of this could the seasonality-induced disruption in the availability of raw materials. In an industry that relies on plant-sourced ingredients, a disruption in the crop cycle can mean a major setback. It can threaten production and therefore cause a major existential crisis. Similarly, weather phenomena like El Niño are also highly probable natural events. Similarly, the quickly escalating geopolitical problems in a country can also become highly probable based upon the past data on such situations. These events require a proactive action plan.

Unlikely events

While we have emphasized the importance of high probable events, we cannot undermine the low probable events in any case. These events, although less probable, can also be examples of supply chain disruptions. Examples of such events could be a global pandemic, terrorist attack, or a stock market crash. These events may not require immediate focus. Another perspective on this can also help us understand and deal with such events better. On an individual level, people fear terror attacks more than diseases like cancer. Although, statistically, the probability of the former is significantly lower. Managerial decisions are quite analogous to individual decisions. We tend to make common mistakes due to our biases.

One of the ways of avoiding these errors is to make scenario-based planning. When we assign a rough probability to an event and list down the possible course of action, we have potentially dealt with the issue before they occur. It is best to plan for the worst but one should have a fairly rational perspective towards the low probability events. Also, when the situation is dynamic and escalates, we can reclassify a low probability event into a high probability one. For instance, if we consider the case outbreak of a new highly contagious viral disease. In such a situation, we can proactively prepare for the disruptions in the supply chain and make alternative arrangements for procurement, transportation, warehousing, etc. to offset some of the impacts.

Develop a proactive strategy towards supply chain disruption

- Continuous monitoring (not a system but as a culture)

- Scenario planning

- Predicting changes in demand and supply

- Speed of reaction

- Post disruption normalization

You may also consider doing an in-depth supply chain disruption analysis. This would help you calculate the total impact of the disruption.