Kodak was founded in 1888 in New York, USA. They dominated the camera market for over a century. However, Canon, a relatively less known Japanese company and also a late entrant, slowly and steadily captured a major part of the camera market. A major upheaval in the camera market took place in the early 2000s. Kodak’s market share gradually declined. It was just a matter of time and eventually, Kodak ran out of steam. They filed for bankruptcy in 2012. On the other hand, Canon saw an increase in the share of the market over the same time period. They fully embraced new technologies and continuously improved their product offerings. One of the key drivers of Canon’s success is its Canon Production System or CPS. CPS is Relatively less known compared to the more popular Toyota Production System. However, it is a remarkable example of using the Kaizen model of continuous improvement.

First, we shall take a look at the Kaizen model and try to understand why it is highly revered by managers worldwide. After that, we shall see some best practices to ensure the successful implementation of Kaizen. Finally, we shall take a deep dive to see how Canon has used the kaizen model of continuous improvement to stay relevant in a competitive market.

Contents

Kaizen – explained in plain English

The term Kaizen needs no formal introduction. It has percolated into the boardroom lingo. In the most literal sense, it means ‘good change.’ However, it encompasses a philosophy of finding ways to improve functions and processes with small, frugal, easy to implement changes. It has been accepted by the Oxford English Dictionary as an English work in the year 1993.

Another aspect of kaizen is ‘continuous improvement.’ This highlights that the importance of the aggregate impact of small increments. It is analogous to the concept of compounding. For example: let’s say that you have a hundred bucks with you and you are able to increase it by 1% every day. Then by the end of the year, you will have three thousand seven hundred bucks. Similarly, if you are able to find new ways to improve your business process by 1% every day you will see a thirty-seven-fold increase in performance. However, practically it is not possible to improve even at 1% every day. Nevertheless, every small improvement will get compounded and you will see meaningful results in the end.

Difference between Kaizen and Innovation

Is Kaizen the same as innovation? Although these terms are similar and have a similar end result in mind, they are very different ways to achieve organizational success. In the simplest sense, Kaizen is one of the approaches to managing innovation. Here are some differences between Kaizen and the traditional approach to innovation management:

| Kaizen | Innovation |

| A subtle approach to improving things by looking at the current setup of technology, process, or formula. Kaizen is therefore called small continuous improvement. | A more dramatic approach where we try to find the application of new technology, process, or formula. |

| Driven by experience while working on the problem or doing day-to-day activities. | Driven by the base of science and technology. The sources of innovation come from new developments or new ways of using existing technology. |

| Zero cost or No cost approaches are the hallmarks of Kaizen improvements. | Innovation management relies heavily on research & development which is an expensive affair. |

| Entails lower risk because the changes are small and have less impact individually. | Innovation can bring major changes which have a greater impact (good or bad) on the final outcome. Therefore they are a riskier affair. |

Kaizen Model of Continuous Improvement

Kaizen can be best understood as a set of management concepts. These concepts highlight how we should use kaizen in our firms. We can use some common management principles to guide us in adopting the kaizen model of continuous improvement in our organization.

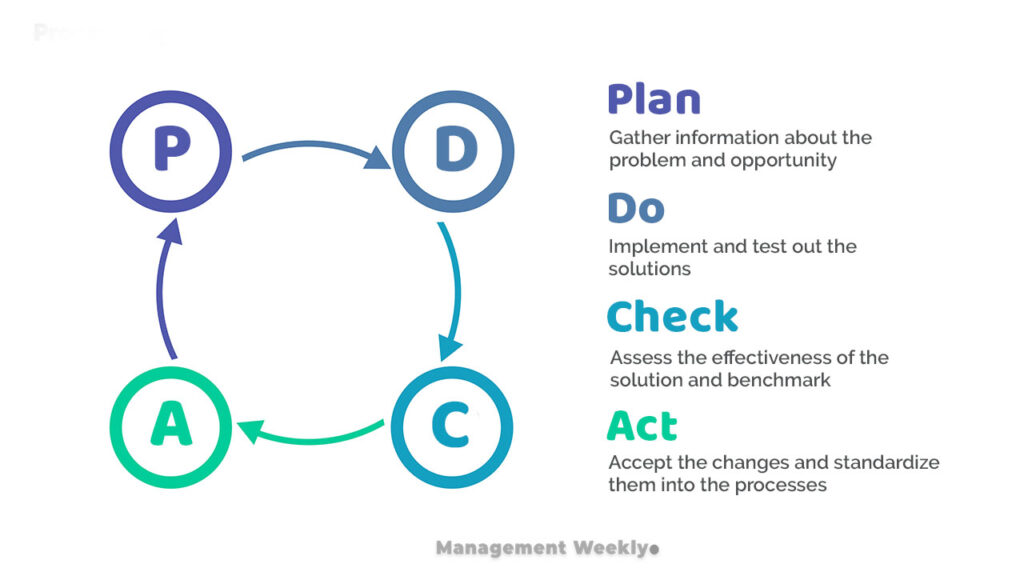

- Plan-Do-Check-Act or PDCA – the PDCA cycle is hallmark of kaizen model of continuous improvement. PDCA represents the different stages of the quality management process. The first step is planning for the improvement. We need to find what are the potential areas for improvement. The second step or do, refers to the act of executing these changes. Subsequently, the third step of check refers to the monitoring of the changes. Finally, the fourth step or act refers to acceptance of the new system or process. In this stage, we accept the new norm and standardize them as a part of the operational process.

- Process focus – the second aspect of kaizen is putting focus on the process of achieving quality rather than running behind the results. This is a major difference between kaizen and western concept of innovation. The original spirit of kaizen calls for driving these changes with the goal of improving things rather than running behind optimizing economic gains. Companies that are successful in implementing the true philosophy of kaizen embrace this zeal of improvement to make things better. It has long lasting impact because intrinsic motivation to improve things is better than external rewards. One of the ways of enabling creative thinking is through brainstorming which is important part of any project management.

Some common managerial issues with Kaizen Model

Saving up and building a corpus for retirement is a simple but effective way to create wealth. However, very few of us are able to set aside a good proportion of our earnings. Two key reasons prohibit us from doing this:

1. Motivation

2. Other commitments

In the same vein, Kaizen also suffers from a lack of motivation. It starts off a ‘flavor of the month’ thing. You will see excited mid-managers putting up posters around the firm calling everyone to join the ‘Kaizen’ movement. However, this does not last long, the focus shifts to some new ‘buzzword’ next month or next week. As we have discussed previously, successful Kaizen needs a long-term commitment. The solution is simple but difficult – treat Kaizen as a cultural goal rather than a performance goal. Japanese firms were excellent places to percolate cultural changes as the society has conformity.

Also, the group dynamics support a unified cultural adoption. It is not very easy to introduce such an organization-wide change in working philosophy in other geographies. Especially those where people have a lower sense of community-based thinking and places where there is a greater focus on end results rather than focusing on the process of getting the results.

Managing challenges associated with Kaizen

| Roadblocks | Potential Solution |

| Status Quo – It is in our nature to not fix something unless it is broken. | Empower your employees to question the processes, systems, and how things are done. Most of the employees feel underconfident in expressing something new in the fear of being rejected, ridiculed, or ignored. Even the most creative individuals in non-receptive teams will learn to ‘keep ideas to themselves |

| Pride & legacy | Another major roadblock is the organizational pride in legacy systems. The sense of pride in one’s systems and processes makes you blind to the numerous doors of opportunity that you cross every day. We have always done it this way is not a justification to stop being creative and thinking of making that process slightly better. |

| Hunting down ‘next big breakthrough’ | It again comes down to the basic instinct of getting fascinated by something new and cool. However, running after the big breakthroughs is expensive. You need a larger outlay for the research and development. It also entails greater uncertainty. On the other hand, one of the often-touted benefits of Kaizen is frugality. Most of these small changes are free or cheaper to implement. Secondly, if small changes fail, you face a smaller loss. |

| Open-loop thinking | Open-loop means that you do not have standardized ways to see if the changes are working or not. When you implement some change, it can either have a positive or negative effect. Your task as a manager is not limited to finding creative solutions and implementing them. The last but vital step is to continuously observe how your changes affect the objectives. |

| Armchair thinking | Some of us are excellent armchair thinkers. It takes little effort to come up with a model, show some projections and impress your bosses. A more effective way of finding solutions to business problems is to focus more on the implementation aspects. This aspect is given the least focus and often delegated to lower managers. The Japanese term ‘Genchi Gembutsu’ prescribes action-oriented management. It suggests that you ‘leave the building,’ go out in the real world, and experience how things are working. |

| No incentive to employees | Imagine a firm that employs only unpaid interns. Will this firm even survive for six months? Why not? Organizational transaction between the employees and employer is based on the simple concept of mutual benefit. Unless there is an incentive for the employee to work, they won’t work. Unless there is an incentive for them to participate in the creative development, they won’t. However, this is one place where the Japanese management system is not the best example. Working hard without any apparent appreciation or rewards is culturally accepted in Japan. On the other hand, the American management style is much better in this regard. Managers appreciate the subordinates with verbal, pecuniary, and social rewards. |

Canon Production System – an example of Kaizen Model

We had opened this article with the example of Canon’s exemplary success story. We had also credited their focus on innovation as one of the key drivers of success. However, innovation is not a one-off thing. Their approach to innovation management is based on the concept of continuous improvement or Kaizen. Here, we shall take a deep dive into how Canon manage their innovation through the CPS or Canon Production System. The various methodologies associated with Kaizen are employed by Canon. These include the following:

Total Quality Management

Most of us may not be aware of the rich legacy of quality management at Canon. It often gets overshadowed by the likes of Toyota as they get cited more often. However, avid readers may be aware that Canon was one of the pioneers of quality management. They coined the punchline ‘No claims, no trouble’ in 1964 and used this as a guideline to direct efforts into improving product quality.

Further, they operationalize the slogan through three working objectives. These can also be summarized as the 3S of canon quality:

The quality logo looks like a Japanese fan. The three blades are Safety, smartness, and Satisfaction. These three aspects have been summarized below. Their kaizen model of continuous improvement is based on the concept that these three must come together to ensure quality. This integrity of three S is represented by the apex of the fan shape where they meet. The diverging shape of the fan also represents the extended influence of their quality concepts. One of the common pitfalls of many quality programs is that they take a too narrow a view of the quality. CPS breaks this trend with a more holistic approach.

| Safety | The sense of quality is extended not just to the defects in the products but to the entire production and usage. No product or process associated with Canon must cause any injuries. Thirdly, these products should not cause any injuries to the users. |

| Smartness | Some functional aspects of the products capture the smartness aspect of the quality. Canon strives to achieve easily of use, simple but functional aesthetics in their products. |

| Satisfaction | The third aspect of quality for Canon is user satisfaction. They strive to not just satisfy the customers but delight them with superior products. |

Kyosei at Canon

Kyosei represents a less popular but futuristic approach to community outlook. It integrates very well with the kaizen model of continuous improvement. Traditionally, we have looked at products as the point of focus for quality improvement. Then we started looking at improving the processes. Further, the concept of Kyosei extends this outlook outside the boundaries of the firm. In the simplest sense, Kyosei is the concept of inclusion where the organizations treat everyone equally regardless of their background.

The top executives at Canon noticed imbalances in their target markets as they expanded into new geographies. Some common imbalances are economic inequality, competitor practices, and political challenges. They strive towards management guidelines that reduce these imbalances. The second set of challenges are related to the sourcing of materials. Canon uses these different challenges as points of improvement for their products and processes. Their model is an example of many such successful implementations of this remarkably simple but effective management philosophy.